I added a new link to Dave's Rio Grande page.

He has some great pics of the tower at Chama

http://davesriogrande.net/Structures/ChamaCoalTower/ChamaCoalTower.htm

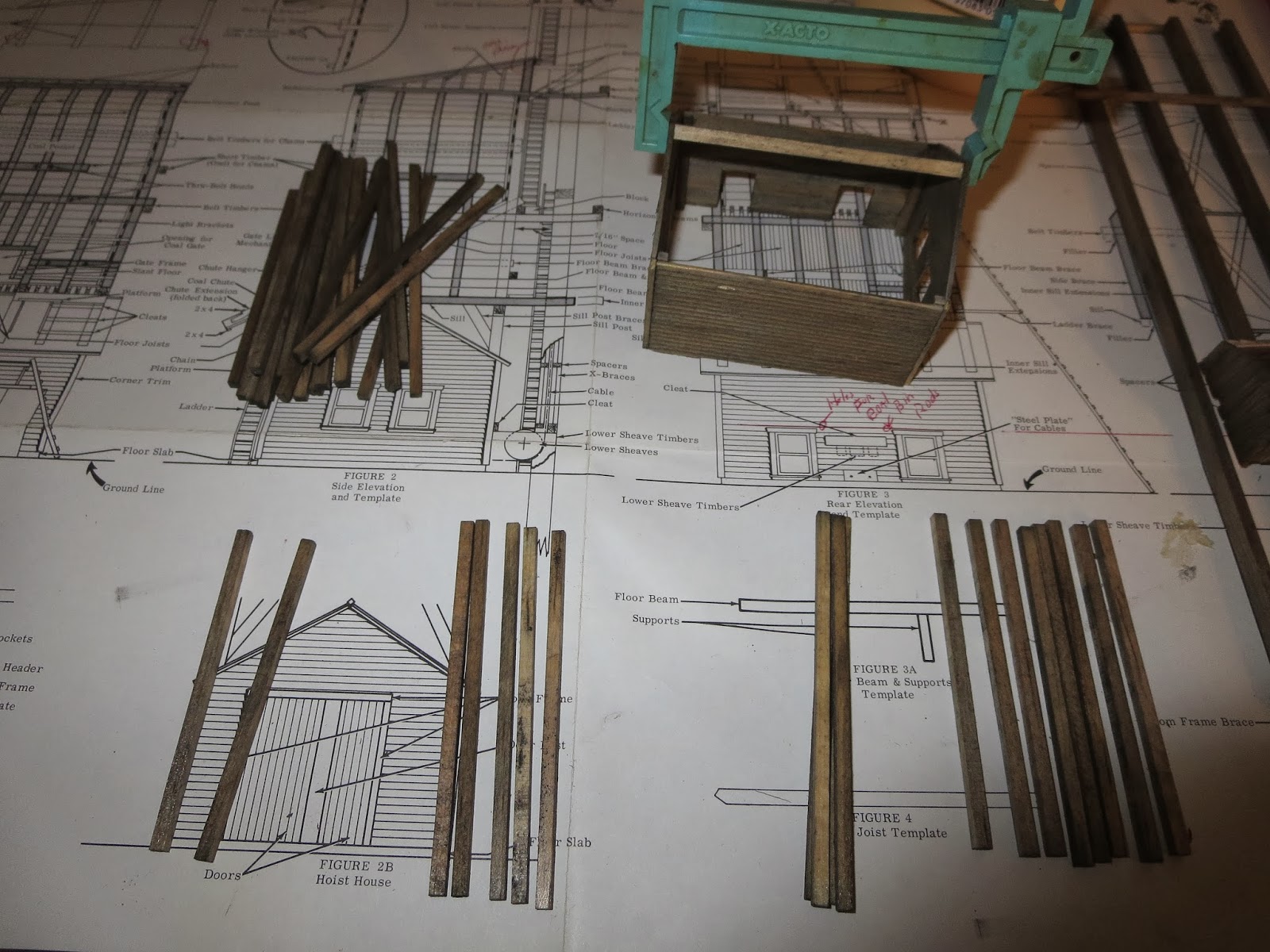

The pic below shows all the sides built up over their templates.

You should not have to cut any parts to fit, they are all precut to the proper lenght, so if a part needs cutting, stop and look for another one. It's there somewhere!

Looking down inside frm the top. I started adding the floor joists

The backside.

The front. I added Grandt line nut/bolt detail.

Test fitting the floor

Below is the real esate template

Youcan see it occupies an area 5 x5.5 inches.

The pit track center line is 1.5 inches from the outside edge.

The track center line for the tower side may depend on what the largest engine you have.

I'm setting mine at 1 inch from the edge of the hoist house (for now)

I cut the paper to the actual dimesions listed and will use it to help me in my track planning on the diorama.

If anyone is building one and would like to share their work, I'll be happy to add your pics